wood hardness test wikipedia|birch on janka hardness scale : factories The test measures the force required to embed a standard-sized steel ball (0.444in/11.28mm diameter) exactly halfway into the surface of a standard-sized sample of the wood. The formal procedure, embodied since 1927 as ASTM . webOnlyFans is the social platform revolutionizing creator and fan connections. The site is inclusive of artists and content creators from all genres and allows them to monetize their content while developing authentic relationships with their fanbase. Just a moment. We'll try your destination again in 15 seconds .

{plog:ftitle_list}

Um novo conceito. Uma forma toda Oggi de surpreender você. Há mais de 10 anos no mercado, a Oggi Sorvetes conta com mais de 700 lojas.

Janka hardness testing. The actual number listed in the wood profile is the amount of pounds-force (lb f) or newtons (N) required to imbed a .444″ (11.28 mm) diameter steel ball into the .The test measures the force required to embed a standard-sized steel ball (0.444in/11.28mm diameter) exactly halfway into the surface of a standard-sized sample of the wood. The formal procedure, embodied since 1927 as ASTM .

The Janka scale is used to determine the relative hardness of particular domestic .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests. The Janka scale, simply put, records the density of wood by testing its resistance to denting. The test measures the force required to embed a .444-inch (11.28mm) diameter steel ball halfway into a piece of wood.

The Janka hardness test measures the resistance of a sample of wood to denting and wear. It measures the force required to embed an 11.28 millimeters (0.444 in) diameter steel ball halfway into a sample of wood. The Janka hardness test measures the amount of force required to embed a 0.444 inch (11.28mm) diameter steel ball into a piece of wood to the depth of half the ball's diameter.

The most common test for testing wood hardness is known as the Janka hardness test. The actual number listed in the wood profile is the amount of pounds-force (lb f) or newtons (N) required to imbed a .444″ (11.28 mm) .

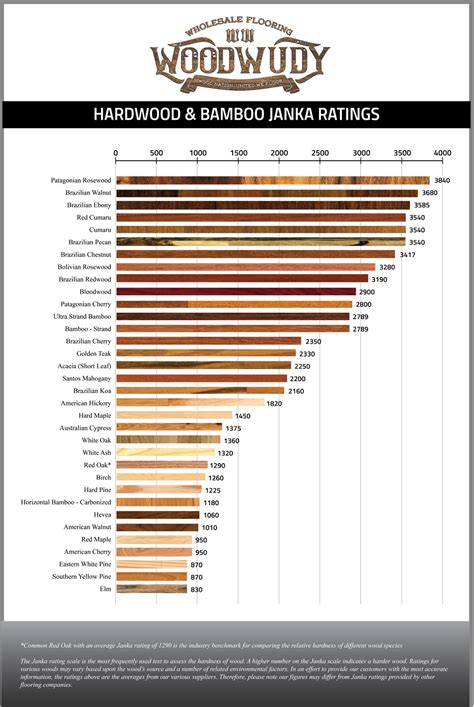

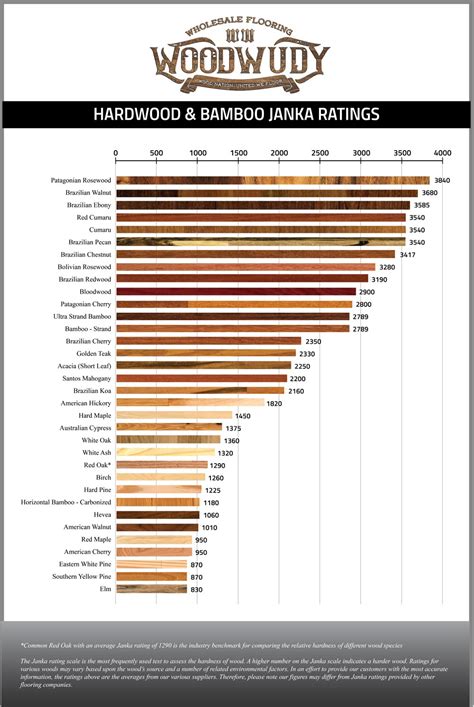

The Janka hardness test is the international standard for measuring the resistance of a sample of wood to denting and wear. It's expressed in pounds-force (lbf). The test actually measures the force required to embed an .The most common test for testing wood hardness is known as the Janka hardness test. The actual number listed in the wood profile is the amount of pounds-force (lb f) or newtons (N) required to imbed a .444″ (11.28 mm) .The Janka scale is used to determine the relative hardness of particular domestic or exotic wood species. The Janka test measures the amount of force required to embed a 0.444" steel ball into the wood to half of its diameter. Woods with a higher rating are harder than woods with a lower rating. The scale used in the table is pounds-force.

This test is known as the Janka hardness test and is widely used in the industry. The higher the Janka value, the harder the wood. The scale ranges from 0 lbf to over 5000 lbf, typically with exotic woods having values .

Development of Janka Wood Hardness Scale The Brainchild of Gabriel Janka. The Hardness Test was developed by Austrian-born American wood researcher Gabriel Janka (1864-1932). Janka’s ingenious method allowed for a more systematic approach to understanding relative hardness of wood, a critical factor that influences the wood’s longevity and suitability for .Brinell hardness test (HB) BHN and HBW are widely used [7] Knoop hardness test (HK), for measurement over small areas, widely used to test glass or ceramic material. [8] Janka hardness test, for wood; Meyer hardness test; Rockwell hardness test (HR), principally used in the USA. HRA, HRB and HRC scales are most widely used.However, to the uninitiated, the concept of wood hardness and the Janka scale may seem abstract and complex. In this comprehensive guide, we will demystify the Janka Hardness Test and its resulting scale. . Janka Hardness Test – Wikipedia. Link; 4130 Durham Road, #110, Roxboro, NC 27574, United States We are located about 10 miles south of .The Janka wood hardness rating scale is determined by the Janka hardness test. The Janka hardness test measures the resistance of a sample of wood to denting and wear. It measures the force required to embed an 11.28 millimeters (0.444 in) diameter steel ball halfway into a sample of wood.

Understanding the durability ratings of hardwood is crucial when making your selection.One key factor to consider is the Janka hardness rating, which measures a wood species’ resistance to wear and denting.The higher the rating, the more durable the wood is. It’s also important to consider the finish of the hardwood, as well as the wood species itself, as .

The most commonly used test to assess the hardness of wood is the Janka hardness test, which measures the resistance of a sample of wood to denting and wear. Technically speaking, it measures the force required to embed a steel ball into a sample of wood, and the resulting rating places that wood species on a scale.Our chart is based on the Janka Hardness Scale which is the industry standard for gauging the ability of various wood species to resist denting and tolerate normal wear. It also indicates the effort required to either nail or saw the particular wood species. The woods are listed from hardest to softest, so the higher the number, the harder the .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum .

Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

The Janka Hardness Scale is essential for determining the resistance of wood to denting and wear. A precise method includes specific testing technique and measurable units. Defining the Janka Hardness Scale. The Janka Hardness Scale ranks wood’s hardness by measuring how resistant different wood species are to denting and wear. The Janka rating is the standard grade used throughout the industry, and it can be used to quantify the hardness of the wood as a material. The exact value provided in the wood profile is the amount of pounds-force .Angles of a Knoop hardness test indenter. The Knoop hardness test / k ə ˈ n uː p / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known (often 100 .

Janka Hardness: 900 lb f (4,010 N) Modulus of Rupture: 9,530 lb f . Monkeypod wood dust has been reported as an eye irritant. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more . I would also recommend first .Recommendations for boards are woods between 800-1500 Janka hardness, preferably end grain so the knife can sink in and then when the knife is removed, the wood can close up after the cut. Even lower on the scale, there are very nice larchwood end grain boards if you go that route.These are just a few of the most popular wood species for kitchen cabinets. If you want to see the full Janka hardness scale, check out this table. How Is Hardness Measured on the Janka Hardness Scale? The Janka hardness test measures the force necessary to embed a 0.444-inch steel ball to half of its diameter into a piece of wood.

Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .A sample of MDF. Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibre, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. [1] MDF is generally denser than plywood.It is made up of separated fibre but can be used as .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

wood janka chart

The Janka hardness scale is a rating system used to determine the relative hardness of different wood species. The scale was invented by Gabriel Janka, an Austrian wood researcher, in 1906, and it measures the . and it measures the force required to embed an 11.28-millimeter-diameter steel ball halfway into a sample of wood. The test is .

Hardness is a measure of how much a material resists changes in shape. Hard things resist pressure. Some examples of hard materials are diamond, boron carbide, . Guidelines to hardness testing Archived 2012-11-28 at the Wayback Machine This page was last changed on 19 May 2022, at 04:49. Text is available under the Creative . Let’s dive into the Janka hardness scale so you don’t make the same mistake I did. What Is the Janka Hardness Scale? The Janka scale, simply put, records the density of wood by testing its resistance to denting. The test measures the force required to embed a .444-inch (11.28mm) diameter steel ball halfway into a piece of wood.Thermally modified wood is engineered wood that has been modified by a controlled pyrolysis process of wood being heated to (> 180 °C) in an oxygen free atmosphere. This process changes to the chemical structures of wood's cell wall components lignin , cellulose and hemicellulose which decreases its hygroscopy and thus increases dimensional .

The Janka hardness scale is a way of measuring the density, hardness and resistance of various wood. The test is named after its creator, Gabriel Janka. This brief guide looks at the Janka hardness scale for testing flooring durability. It explores common hardwoods that have a good rating on the Janka scale.

wagner moisture meter accuracy

wagner moisture meter calibration

60:54 2H. Lecce 0 Inter Milan 3 More. See More Markets. GER Bundesliga. 1 X 2. NS. Augsburg 0 SC Freiburg 0 More. 11/8 13/5 . BV Gaming Limited (trading as “BetVictor”), a company registered in Gibraltar (company registration number 42734). BetVictor’s registered office is located at Suite 23, Portland House, Glacis Road, Gibraltar .

wood hardness test wikipedia|birch on janka hardness scale